65cm3/h

The company's self-developed AFS-M400 selective zone laser melting 3D printer.

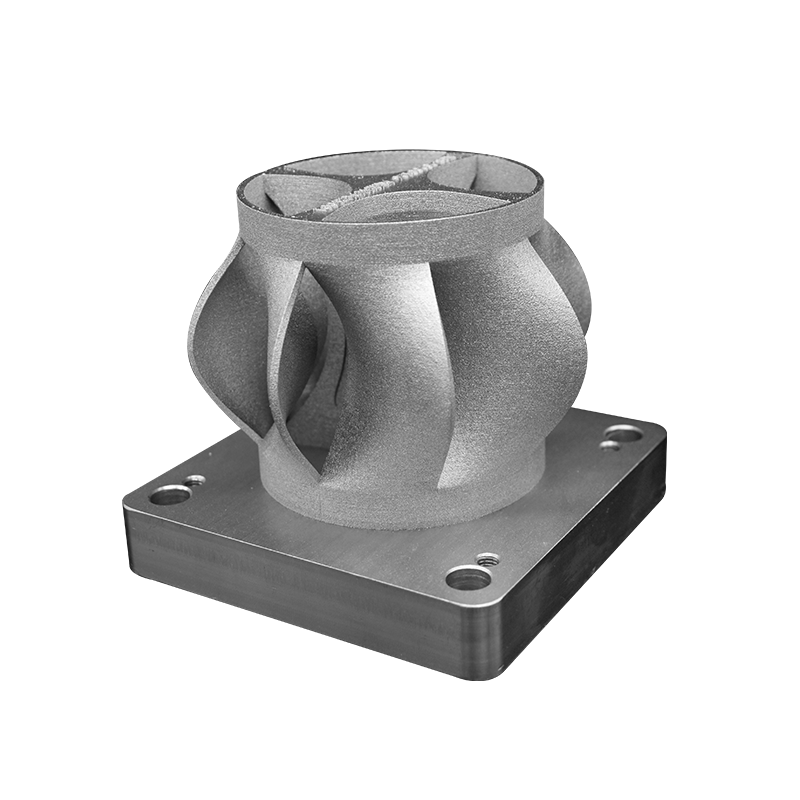

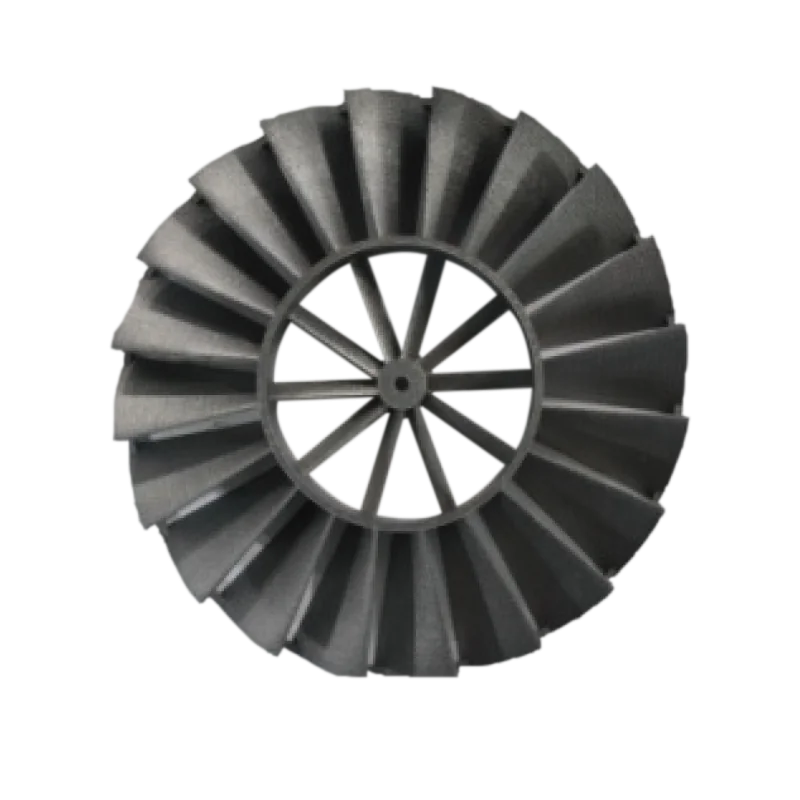

The equipment utilizes laser melting technology to selectively scan the metal powder according to the layered cross-section information of the digital model, and finally melt and form layer by layer. The equipment has the features of high molding precision, good stability, user-friendly interaction and high safety. It adopts the design of high sealing molding room, advanced optical system, excellent wind field design, high precision servo motor and screw and other transmission mechanism to ensure stable molding precision and speed, stable operation and simple operation of the equipment, and adopts the safety design of sealing operation of the powder, anti-static treatment and explosion-proof safety treatment to achieve Real-time monitoring of the working status of the equipment, abnormal automatic alarm to ensure the safe and reliable operation of the equipment.

The finished metal parts printed with high precision, strength and other characteristics, suitable for stainless steel, titanium alloy, aluminum alloy, mold steel, cobalt-chromium alloy, nickel-based alloy and other metal products of the integrated molding.

Address:No.7 Jin Yi Street, Shunyi District, Beijing, China

Tel: 010-62117806

E-mail: [email protected]